What decoration services does JPS Packaging provide?

JPS provides a full range of cosmetic packaging decoration services to help brands create packaging that stands out. Options include in-mold coloring for vibrant, lasting shades; inner and outer spray finishes such as pearl, matte, soft touch, glossy, and frosted; metallization for a premium reflective effect; hot stamping for metallic logos and accents; silk screen printing for sharp, durable designs; and heat transfer or digital printing for detailed, flexible artwork.

What is in-mold color?

In-mold coloring integrates pigment directly into the raw material during the injection molding process.

How it works:

• Pigments are compounded into the base resin.

• During injection molding, the colored resin is shaped into the final component.

Key enefits:

• The color becomes an intrinsic part of the packaging.

• Delivers long-lasting, uniform shades that will not chip, fade, or scratch.

• Eliminates the need for secondary painting or coating, reducing cost and environmental impact.

What is spray coating?

Spray coating is a versatile decoration process that applies to a thin layer of finishing directly onto glass or plastic packaging.

Available finishes include:

• Frosted

• Soft Touch

• Matte

• Glossy

• Gradient

• Multi-color effects

Key Benefits:

• Enables brands to achieve custom textures and visual impact.

• Expands creative possibilities with both subtle and bold aesthetics.

• Enhances self appeal without changing the underlying packaging structures.

What is inner spray coating?

Inner spray coating is a decoration process where color or effects are applied to the inside surface of glass or plastic containers.

Key Features:

• Creates a premium, layered appearance with depth and dimension.

• Allows for unique effects such as gradients, metallic tones, and translucent finishes.

• Protects the exteror from sractches since the coating is applied internally.

Brand advantages:

• Delivers a luxurious, high-end presentation that elevates the product's perceived value.

• Ideal for prestige beauty, fragrance, and skincare packaging.

What is metallization?

Metallization is a vacuum-based process that deposits a microscopically thin metal layer onto prepared plastic or glass components to deliver a mirror-like, chrome aesthetic. After deposition, a protective topcoat locks in the finish and shine.

Key Benefits:

• Mirror-like impact: Ultra-high gloss, reflective “chrome” look that reads premium on shelf—ideal for beauty, skincare, and fragrance lines

• Color & gradients: Can be produced in virtually any color (via tinted topcoats) including gradient effects for elevated visual depth.

• Works across formats: Compatible with both plastics and glass components, enabling cohesive looks across full ranges

• Uniform, consistent coverage: Vacuum application with part rotation yields even deposition over complex shapes; the topcoat preserves gloss and appearance.

What is heat transfer printing?

Heat Transfer Finish is a decoration method where pre-printed designs are transferred from a film onto packaging using heat and pressure. The artwork bonds directly to the container, creating a smooth, label-free look.

Key Benefits:

• High-resolution graphics, including gradients and fine details

• Premium, seamless finish with no label edges

• Strong adhesion and long-lasting durability

• Fast application suited for large-scale production

• Versatile for plastic and glass packaging

What is silk screen printing?

Silk Screen Printing is a decoration process where ink is pushed through a fine mesh screen directly onto the surface of packaging. Each color is applied separately, allowing for bold, opaque designs that stand out on glass, plastic, and metal containers.

Key Benefits:

• Durable & long-lasting: Resistant to scratching, rubbing, and fading with JPS selected ink

• Premium look: Produces bold, vibrant colors and sharp details.

• Versatile: Works on flat and curved surfaces across glass, plastic, and metal packaging.

• Customizable: Perfect for logos, text, and simple artwork in one or multiple colors.

• High-quality finish: Adds a tactile, elevated effect that enhances brand identity.

What is UV coating?

UV Coating is a finishing process that applies a protective and decorative layer onto packaging, then cures it instantly under ultraviolet (UV) light. This technique can create either a high-gloss shine or a frosted matte effect, enhancing both look and feel.

Key Benefits:

• Enhances visual appeal: Creates a premium glossy or matte finish that makes packaging stand out.

• Improved durability: Adds resistance to scratches, scuffs, and everyday wear.

• Versatile finishes: From, sleek shine to soft-touch matte, adaptable to brand style.

Retail impact: Inceases shelf presence with eye-catching surfaces.

What is hot stamping?

Hot Stamping is a decoration process that uses heat and pressure to apply metallic or colored foils onto the surface of packaging. This creates a striking, high-end look that elevates the overall brand image.

Key Benefits

• Luxurious appearance: Delivers a premium finish with metallic shine.

• Versatile options: Available in gold, silver, brushed aluminum, or custom colors.

• High-end branding: Perfect for logos, accents, and design highlights.

• Durable finish: Resistant to fading, maintaining brilliance over time.

What is soft touch coating?

Soft Touch Coating is a finishing technique that gives packaging a smooth, velvety feel. Applied as a protective layer, it transforms ordinary surfaces into premium, tactile experiences that connect with consumers on an emotional level.

Key Benefits:

• Luxury texture: Adds a soft, matte, velvet-like touch that feels premium in hand.

• Enhanced consumer interaction: Encourages customers to pick up and engage with the product.

• Brand differentiation: Creates a sensory signatures, popular in skincare, cosmetics, and babycare packaging.

• Durability: Provides protections against fingerprints, scuffs, and light scratches.

What is water transfer printing?

Water Transfer Printing, also known as Hydrographic Printing, is a decoration process that uses water-activated films to apply intricate patterns and designs onto packaging. The film wraps seamlessly around 3D surfaces, making it ideal for complex shapes.

Key Benefits:

• Seamless coverage: Designs wrap evenly around curves, edges, and textured surfaces.

• Creative flexibility: Enables intricate patterns such as wood grain, marble, camouflage, or custom graphics.

• Material versatility: Works on plastic, glass, metal, and more.

• Preminum look: Enhances packaging with unique, eye-catching effects that stand out on shelf.

What is offset printing?

Offset Printing is a decoration method commonly used for plastic and aluminum tubes. The process transfers ink from a plate to a rubber blanket, and then directly onto the curved tube surface. This allows for precise, multi-color printing that wraps seamlessly around the tube body.

Key Benefits:

• High quality graphics: Produces sharp images, text, and fine details.

• Multi-color capability: Suppots CMYK and Pantone colors for accurate brand matching.

• Cost efficient for volume: Ideal for medium to large prodcution runs.

• 360° decoration: Enables full-wrap designs around tubes without seams or labels.

• Consistent results: Delivers uniform colors and finishes across large quantities.

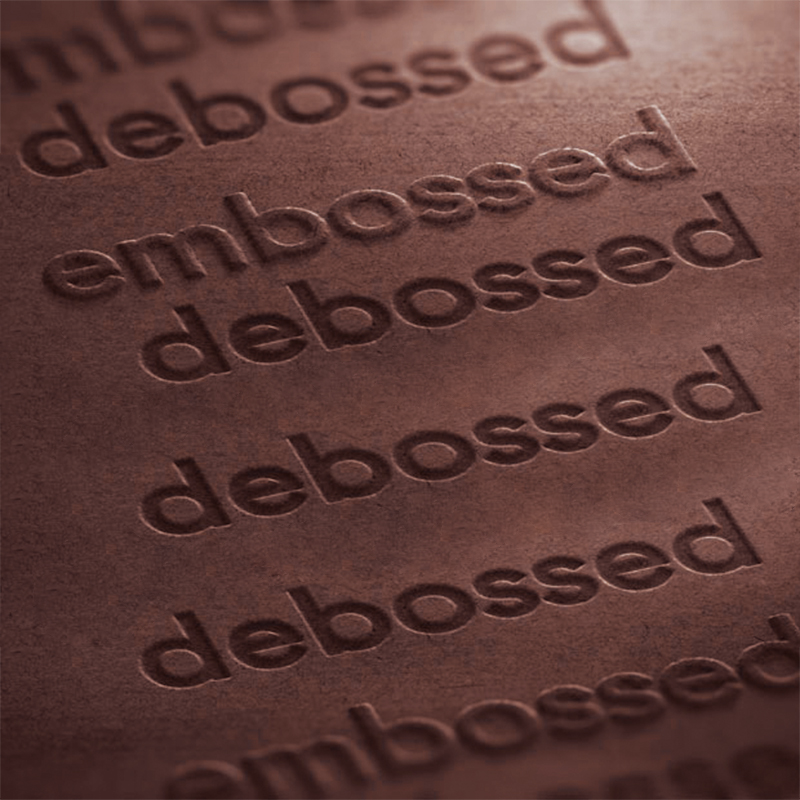

What are embossing and debossing?

Embossing raises designs above the surface, while debossing creates recessed impressions. Both add texture and depth to packaging, making logos and branding elements visually striking and tactilely engaging.

What is a resin (marble effect) finish?

A resin finish is a decorative technique that applies a clear or tinted resin layer to the surface of packaging, creating a smooth, glossy, and durable coating. When combined with pigments or patterns, it can replicate natural effects like marble, stone, or granite, giving each piece a unique, luxury appearance. Resin finishes not only enhance color depth and vibrancy but also provide protection against scratches and wear, making them ideal for premium beauty, skincare, and fragrance packaging.

What is holographic or iridescent finish?

An iridescent finish gives packaging a pearl-like, shimmering effect that shifts between colors under different light and angles. Unlike bold holographic patterns, iridescence creates a soft, elegant glow with pastel or rainbow tones, perfect for cosmetics, skincare, and luxury packaging that want a modern yet refined look.

You may want to know

1. Why is decoration important for beauty and skincare packaging?

High-quality decoration transforms packaging into a powerful branding tool. The right finish not only enhances shelf appeal but also communicates brand identity, product quality, and sustainability values. With consumers making quick purchasing decisions, decoration plays a key role in capturing attention and building brand loyalty.

2. Can decoration be customized to match my brand identity?

Yes. All our finishing options are fully customizable in terms of color, texture, and effect. Whether your brand requires luxury packaging finishes, sustainable matte coatings, or bold metallic accents, JPS ensures precise execution that aligns with your design vision.

3. Do decoration options work across different packaging types?

Our decoration services can be applied to a wide variety of cosmetic packaging — including bottles, jars, tubes, pumps, compacts, and custom designs. No matter the format, our team ensures consistency, durability, and premium presentation.

Searching for sustainable, cost-efficient packaging that fits your brand?

Contact us today!